|

| Res-Kem's New Jersey Service Center Opened in November |

Contact me if you want to receive an invitation.

|

| Res-Kem's New Jersey Service Center Opened in November |

|

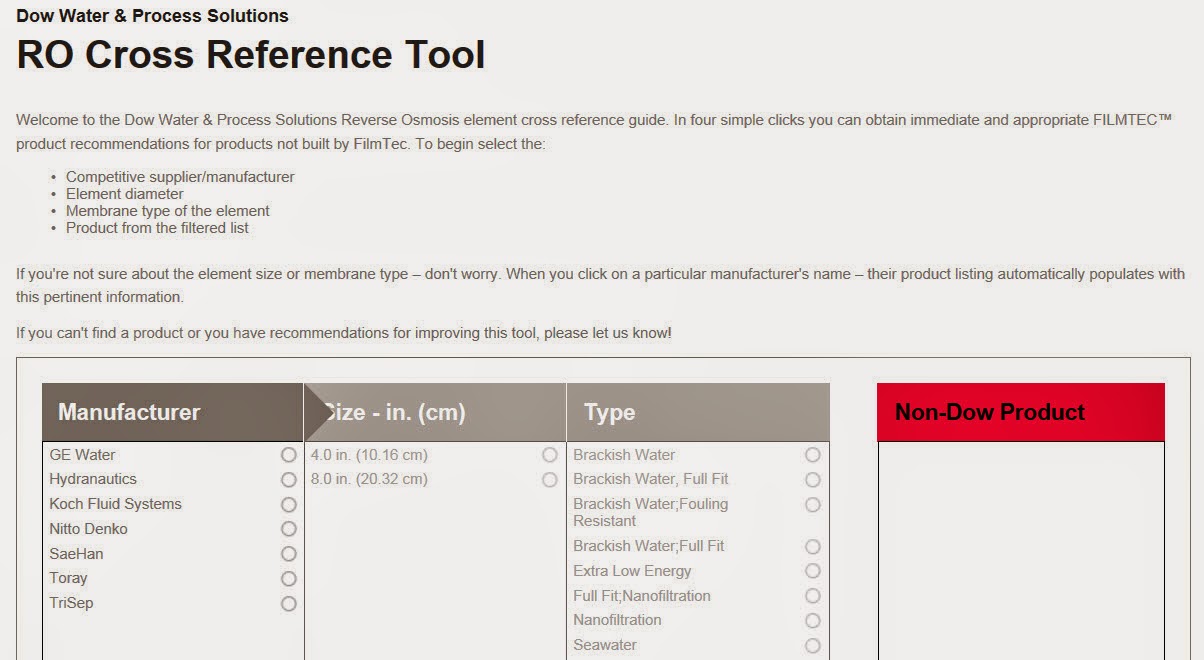

| RO Cross Reference from Dow Chemical Company |

|

| Dual 30" diameter Skid-Mounted Water Softener |

|

Water

treatment application:

|

Softener for boiler feed water

|

|

Savings

and/or ROI the customer wants to achieve:

|

Replacing old system

|

|

Operating

conditions:

|

24/7 operation, boiler make up

|

|

System

configuration:

|

Dual alternating

|

|

Materials

of construction:

|

30" diamter Steel tanks, skid mounted,

Cast Iron Aquamatic valves

Schedule 40 Black Iron

Interconnecting Pipe

|

|

Threaded

or welded:

|

Threaded

|

|

Type

of valves and actuators:

|

Aquamatic V42 Series Cast Iron

|

|

Control

philosophy:

|

Metered, Aquamatic controller

|

|

| BEFORE - Existing Softeners During Tearout |

|

| AFTER - New Dual Res-Kem Softeners Installed After Building Refurbishment |

|

Water treatment

application:

|

Replacing 25 year old zeolite softeners

|

|

Savings and/or ROI

the customer wants to achieve

|

Clean up the zeolite operations and the room where they

reside. Automate the regeneration process and the monitoring of the water

softeners

|

|

Operating

conditions:

|

60-120 gpm boiler make-up

|

|

System

configuration:

|

Singe or Dual Parallel operation PLC controlled

|

|

Materials of

construction:

|

Since the source water being well water and the room

ambient air temperature can be very hot > 95 F, condensation that can form on the tanks, therefore fiberglass tanks were used.

Schedule 80 CPVC was used to provide more strength to the

system piping

Valves were Bray butterfly valves all stainless wetted parts

|

|

Threaded or welded:

|

Glued, Schedule 80 CPVC

and flanged unit piping

|

|

Type of valves and

actuators:

|

All Bray valve Lug style, 150 ANSI flanges.

Solenoid were mounted directly on each valve to save

wiring costs back to panels

|

|

Control philosophy:

|

The plant standardized their automation based upon

Rockwell automation, so we provided the regeneration sequence and the

necessary P&ID so their in-house PLC programmer. His

panel shop could outfit a local panel and Ethernet connection back to the

main powerhouse control room.

|

|

| Front Page of Ecommerce Site |

|

| Interactive Drawing for Pentair Fleck 2750 Valve |

|

| Sodium Cycle Condensate Polisher for Ontario Power Plant |

|

Company

|

Combined Cycle Power plant

|

|

Water Treatment

Application

|

Condensate Polisher to scavenge trace hardness and iron from

returning condensate

|

|

Savings and/or ROI

|

Loss Prevention keeping heat transfer surfaces clean and

reliable for years of trouble free operation

|

|

Operating Conditions

|

Return Condensate flow rate is between 30-90 gpm

|

|

System Configuration

|

24” diameter Simplex

|

|

Materials Of

Construction

|

304 Stainless Steel, CRN code stamped pressure vessel

|

|

Piping Construction

|

All Welded and Flanged Face 304 Stainless Steel piping

|

|

Type Of Valves And

Actuators

|

All Bray valve Lug style-

150 ANSI flanges

|

|

Control Philosophy

|

Customer supplied their own PLC panel. Res-Kem supplied

the enclosure with DIN rail mounted solenoids. Enclosure also had room for customer

supplied HMI

|

|

Options

|

CRN code stamped pressure vessel

Sub-surface wash

|

|

| Dual Skid-Mounted Condensate Polisher for District Heating Plant in Michigan |

| Customer: | Utility District Heating |

| Water treatment application: | Condensate Polisher to scavenge trace hardness and iron |

| Expected savings: | Loss prevention keeping heat transfer surfaces clean and reliable for years of trouble free operation |

| System configuration: | Dual Parallel. On-Board Controller has a relay to indicate start and stop of regeneration process on each polisher vessel. The plants in house DCS system then ramps down the flow rate to each condensate polisher based upon regeneration schedule and times |

| Materials of construction: | Pressure vessels are 304 stainless steel with 125 psig ASME code stamped All face piping is welded and flanged Schedule 40 SS 304ss welded to B31.1 standards |

| Valve and actuators type | All automated valves are Bray valve Lug style for 150 ANSI flanges. Actuators are Bray pneumatic. |

| Control philosophy: | The utility didn’t want to reinvent a control scheme within their DCS, so the off the shelf controllers are being used locally to control both units. System parameters like individual tank flow and regeneration status are outputted to the plants DCS system. |

|

| Front and Side View of Triple Rental Condensate Polishing System |

|

| Back Side of the 3D Printed Model of the Modular Res-Kem Condensate Polisher |

|

| Doug Haring-CWS-VI of Pentair presenting information on the problems with high or low pH in water |

|

| Pentair 3900 Multi-port Valve on Poly-lined FRP tank |